Heat Exchangers

Versatile, Flexible and Efficient

With its diverse selection of heat exchange technologies, Exergetica reaches customers in global markets for power generation, oil and gas, chemistry, marine applications, climate and environment, food and beverages, and transportation. These include plate heat exchangers, shell and tube heat exchangers, finned-tube heat exchangers.

For more information visit our website : heax.fr or contact us : HEAX@exergetica.fr

Submit an information request form and someone will get back to you within 48 hours.

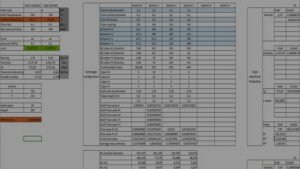

Thanks to its latest calculation software to design and to manufacture heat exchangers, EXERGETICA offers the best technical solution with an optimal cost benefit ratio according to client needs and all international standards.

Sale

For more information, please contact us at HEAX@exergetica.fr

OUR SERVICES

- Design expertise: We customize solutions based on your design parameters

- Numerical Modeling: We have built a library of data to increase the accuracy of our design models beyond the available data of the limited heat exchangers in the literature

- 3D Printing/Additive manufacturing: We enable you to create complex and super-performant heat transfer structures, even in tight spaces, that traditional manufacturing cannot achieve.

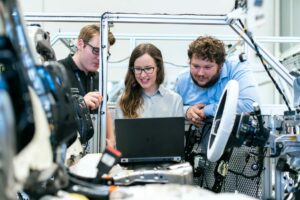

- Testing & Experimental Validation: We perform thermal and hydraulic characterization as well as endurance tests to validate the design and the strength of the designed heat exchangers

Our Heat exchangers line offers a design-to order process, with your application needs as the starting point. We optimize the total quotation process and tailor our manufacturing to fulfil your requirements. We start with the widest possible product portfolio, offered in our selection software.

Design and Manufacturing of a Heat Exchanger

Step 1: Thermal-mechanical calculation

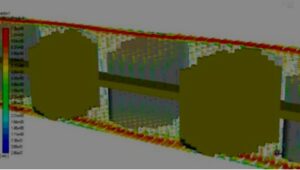

Step 2: CFD modeling and local optimization

Local parametrical and topological optimization can be performed to enhance the performance of the heat exchanger and reduce its cost

Step 3: Manufacturing plans

Step 4: Manufacturing

APPLICATIONS

Whether you are in the automotive industry, agri-food sector, pharmaceutical industry, construction (BTP), or any other sector, our heat exchangers are designed to meet your specific needs.

Construction sector

Nuclear

Automotive industry

Foundry

Malls

Pharmaceutical industry

Materials used in the manufacturing of exchangers

- Stainless steel 304L, 316L, 316Ti, 321, 310S

- Inconel

- Titanium