Our Innovative design, reduce thermal losses while maintaining the heat exchanger highly customizable for different applications from the car industry to high temperatures furnaces.

Shell & Tube equipment comprises a vast range of products that are suitable for a wide spectrum of applications. These applications can vary from basic low-temperature environments to advanced reactors engineered to meet the rigorous demands of high-pressure and high-temperature settings.

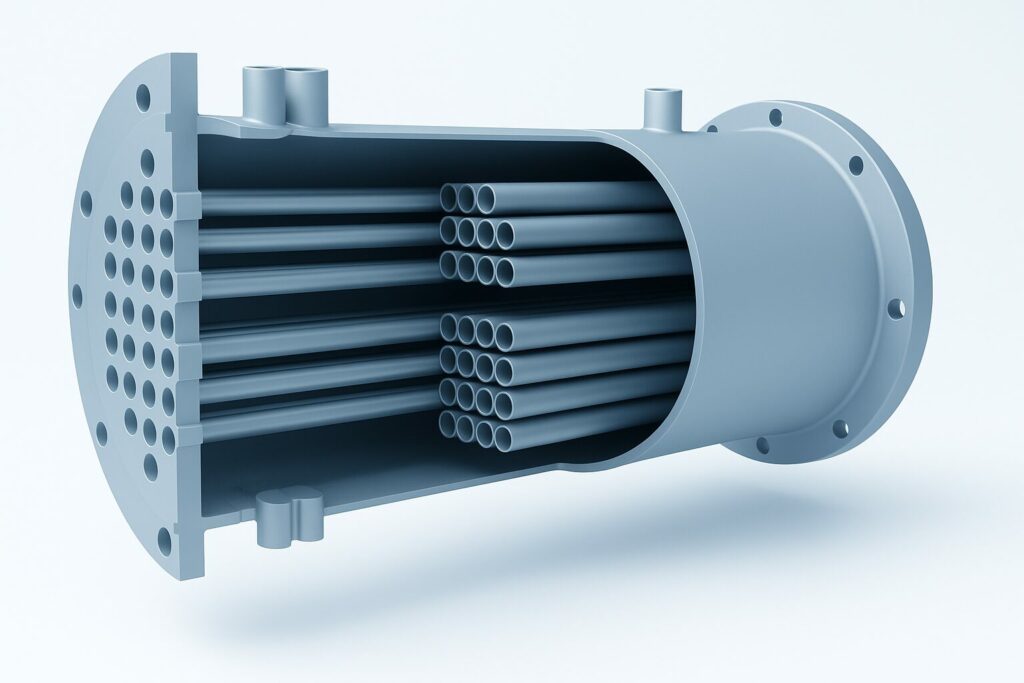

Our patented design comprises a series of expanded tube bundles from the center toward the extremities. Hot gases/liquids enter the heat exchanger from the center, which limits heat losses to the environment and reduces the temperature of the external walls. Its unique design enables it to function in a counterflow arrangement, which increases its thermal performance compared to traditional shell and tube configurations.

Its modular design makes it extremely versatile and easy to service in different applications